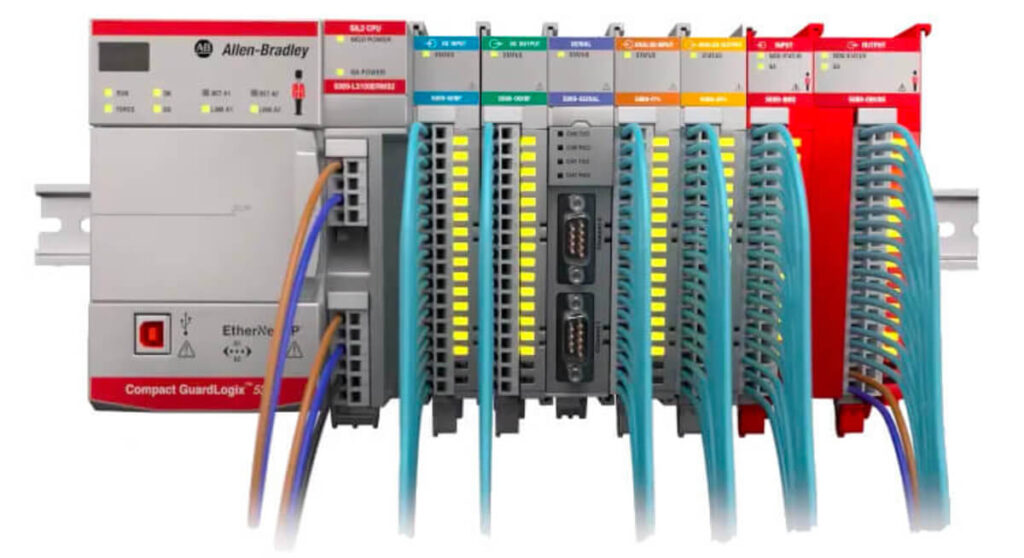

What are I/O Modules?

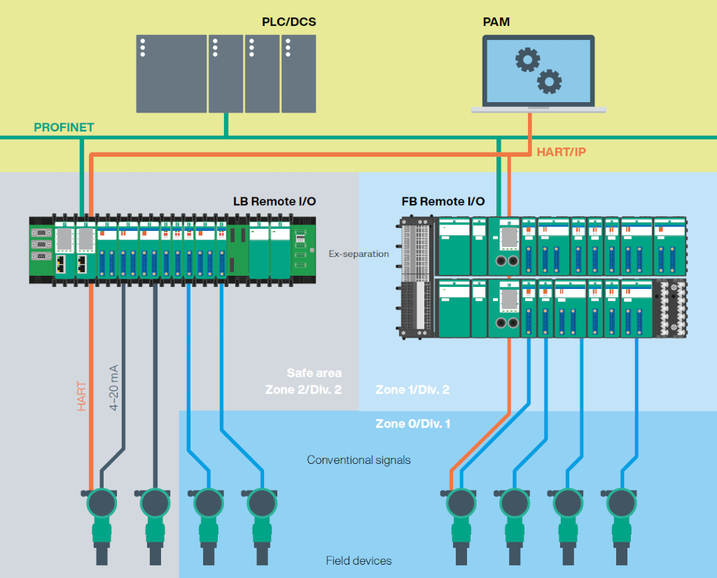

I/O modules serve as the vital interface between the physical components of an industrial system and the digital control system. They enable the exchange of data between sensors, actuators, and programmable logic controllers (PLCs). In simpler terms, I/O modules act as the “ears and mouth” of an automated system.

Types of I/O Modules

I/O modules come in various types, each designed to handle specific types of signals.

- Digital I/O: These modules process on/off signals, such as those from limit switches or relays. They are ideal for simple binary operations, like detecting whether a device is on or off.

- Analog I/O: Analog modules handle continuous signals, like temperature or pressure measurements. They provide precise control and monitoring in applications where values fluctuate smoothly over a range.

- Specialty I/O: Specialized modules cater to specific applications, such as high-speed counting, communication, or safety functions. These are designed for tasks that require exceptional performance in niche areas, such as vibration monitoring or motion control.

How I/O Modules Work

An I/O module typically consists of input terminals, output terminals, and signal conditioning circuitry. Input signals from sensors are converted into a format that the PLC can understand. Conversely, output signals from the PLC are converted into a form suitable for driving actuators. This conversion ensures that data can flow seamlessly between the real world (physical signals) and the control system (digital commands).

Advantages of Using I/O Modules

- Flexibility: I/O modules can be easily configured and expanded to accommodate changing system requirements. They can be swapped out or added without major system disruptions.

- Reliability: Modern I/O modules are designed to operate in harsh industrial environments and offer high reliability, even in extreme conditions such as high temperatures or electromagnetic interference.

- Modularity: I/O modules can be combined to create customized systems tailored to specific applications. This modularity allows for scalability and adaptability in complex automation setups.

- Integration: I/O modules seamlessly integrate with other automation components, such as PLCs, HMIs, and SCADA systems. This enables efficient communication and coordination across an entire system.

Applications of I/O Modules

I/O modules find widespread applications across various industries, including:

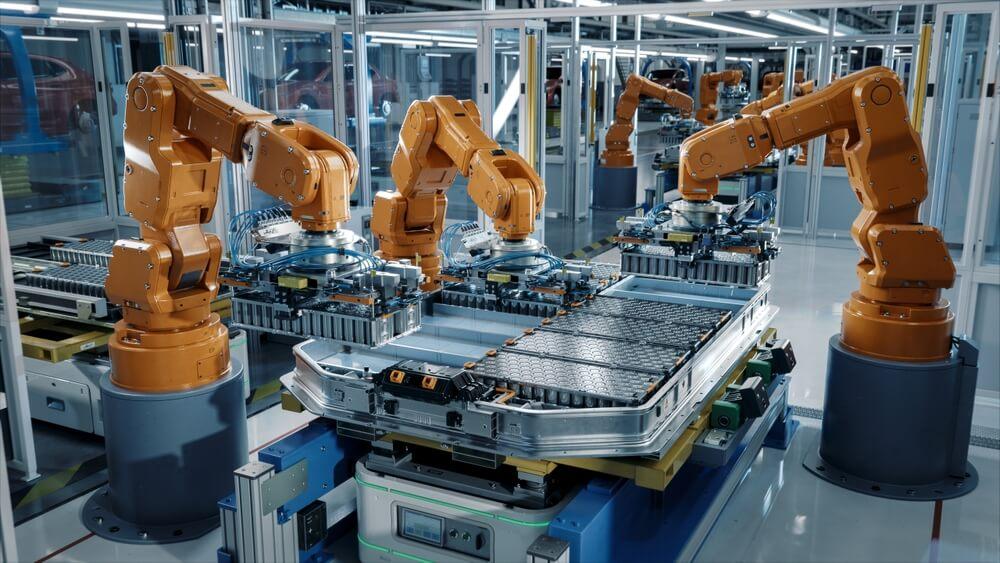

- Manufacturing: Monitoring and controlling production processes, such as assembly lines or CNC machines.

- Process control: Regulating temperature, pressure, and flow rates in industries like oil and gas, chemical production, and food processing.

- Building automation: Controlling HVAC systems, lighting, and security in commercial and residential buildings.

- Robotics: Interfacing with robotic arms and sensors for tasks like pick-and-place operations, precision assembly, and inspection.

The Future of I/O Modules

As industrial automation continues to evolve, I/O modules are becoming more intelligent and integrated. Trends such as the Internet of Things (IoT) and Industry 4.0 are driving the development of advanced I/O modules with enhanced capabilities. These next-generation modules offer features like wireless connectivity, real-time data processing, and AI-driven diagnostics, further improving the efficiency and reliability of industrial systems.