Introduction

In the realm of industrial machinery, ensuring operational reliability and preventing unexpected downtime is paramount. Bently Nevada, a GE company, offers a range of solutions designed to monitor the health and performance of critical equipment. Among these solutions, the Bently Nevada 21000 Proximity Probe Housing Assemblies play a crucial role in providing accurate and reliable measurements of shaft vibration and position. This article delves into the intricacies of these assemblies, exploring their working principles, applications, advantages, and more.

Working Principles

The 21000 Proximity Probe Housing Assemblies work with proximity probes, which are non-contact sensors that measure the distance between the probe tip and a conductive target, usually the shaft of a rotating machine. The housing assembly provides a stable and secure mounting for the proximity probe, ensuring accurate and consistent measurements.

The proximity probe sends out a high-frequency signal, which reflects back to the probe when it encounters the conductive target. The sensor measures the time it takes for the signal to travel to the target and return. The system then converts this time into a voltage signal, which corresponds to the gap between the probe and the target.

Applications

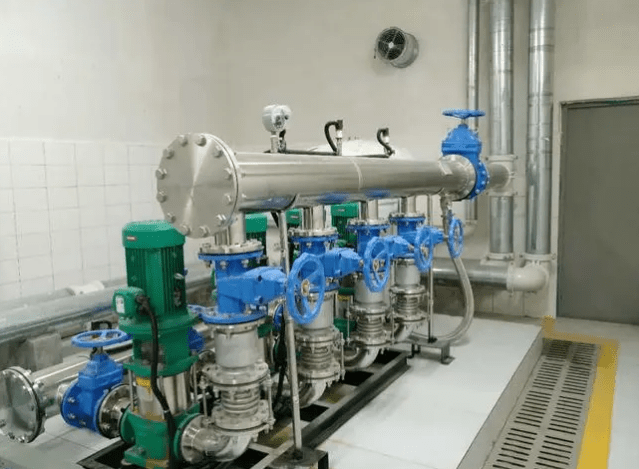

The 21000 Proximity Probe Housing Assemblies find applications in a wide range of industries, including:

- Power Generation: Monitoring the vibration and position of turbine shafts, generators, and other critical equipment.

- Oil and Gas: Ensuring the reliable operation of pumps, compressors, and other rotating machinery in refineries and pipelines.

- Manufacturing: Detecting imbalances, misalignments, and other issues in motors, fans, and other production equipment.

- Pulp and Paper: Monitoring the condition of rollers, pumps, and other machinery in paper mills.

Advantages

The 21000 Proximity Probe Housing Assemblies offer several advantages, including:

- Accurate Measurements: The stable mounting provided by the assembly ensures accurate and consistent measurements of shaft vibration and position.

- Robust Construction: The assemblies are designed to withstand harsh industrial environments, ensuring reliable performance in demanding applications.

- Easy Installation: The assemblies are designed for easy installation and maintenance, reducing downtime and costs.

- Wide Range of Configurations: The assemblies are available in a variety of configurations to suit different applications and probe types.

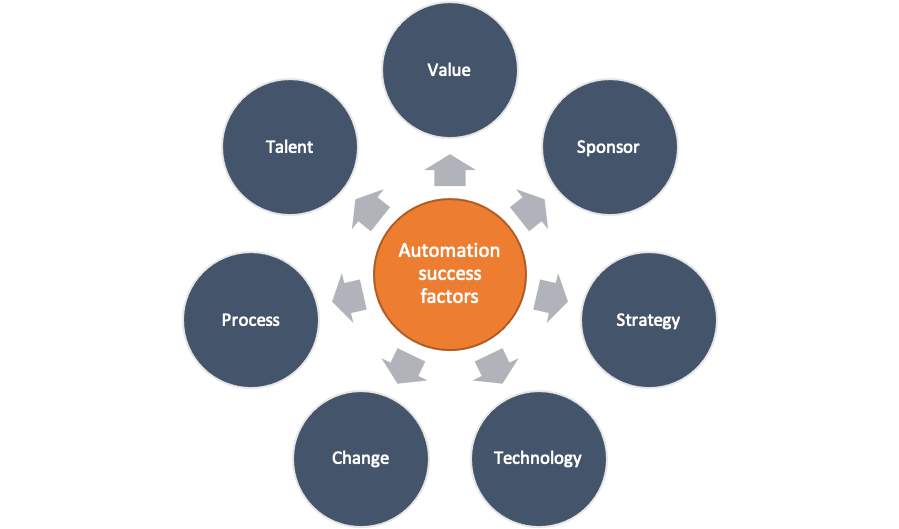

Conclusion

The Bently Nevada 21000 Proximity Probe Housing Assemblies are essential components in ensuring the health and reliability of critical machinery in various industries. Their accurate measurements, robust construction, and ease of installation make them a valuable tool for condition monitoring and predictive maintenance programs. By providing early detection of potential issues, these assemblies help prevent costly downtime and ensure the safe and efficient operation of industrial equipment.