How the PROXPAC XL Proximity Transducer Assembly Works

The Bently Nevada PROXPAC XL Proximity Transducer uses eddy current technology to detect vibrations and positional changes in rotating machinery. A high-frequency oscillator generates an electromagnetic field through its probe. When the target surface moves, eddy currents shift, altering the field’s amplitude. This change converts into voltage signals for precise displacement measurement. The system ensures real-time monitoring of shaft dynamics, critical for predictive maintenance.

Core Functions of the Bently Nevada PROXPAC XL Proximity Transducer System

This assembly measures axial and radial vibration, shaft position, and speed in industrial equipment. It detects early signs of misalignment, imbalance, or bearing wear. Integrated signal conditioning ensures noise-free data transmission. The transducer supports dynamic range adjustments for diverse machinery types. Its diagnostics enable rapid fault detection, reducing unplanned downtime.

Key Technical Features

PROXPAC XL offers rugged construction for harsh environments (up to 120°C). Its modular design simplifies installation and maintenance. Wide frequency response (0-10 kHz) captures detailed machinery behavior. Built-in temperature compensation enhances accuracy. Dual-channel configurations allow multi-parameter monitoring. Compliance with global safety standards ensures reliability.

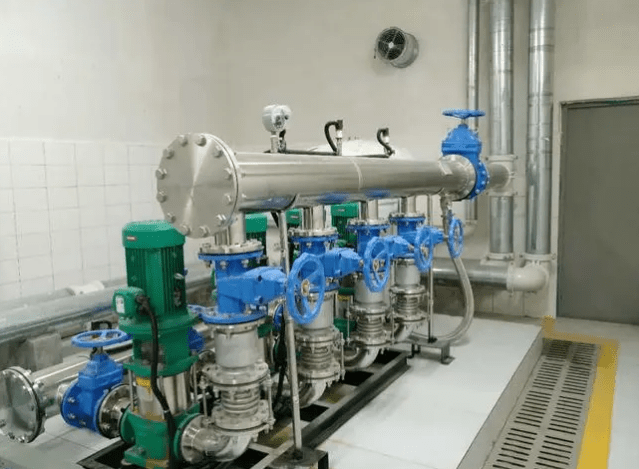

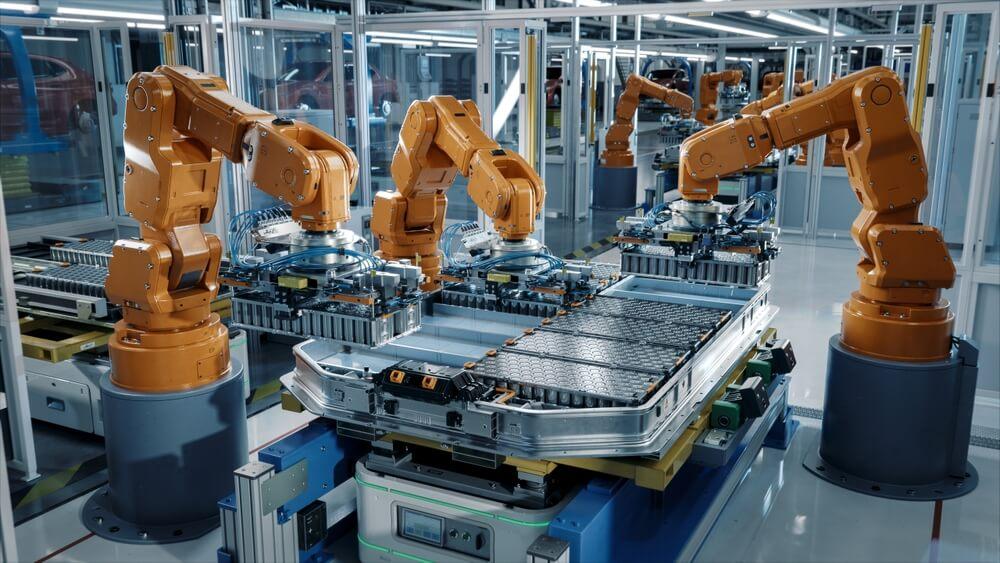

Industrial Applications

It is widely used in turbines, compressors, pumps, and generators. Critical in oil/gas, power generation, and manufacturing sectors. Monitors gearboxes, motors, and rotating assets in heavy industries. Supports condition-based maintenance in aerospace testing rigs. Ideal for high-speed machinery requiring precision data.

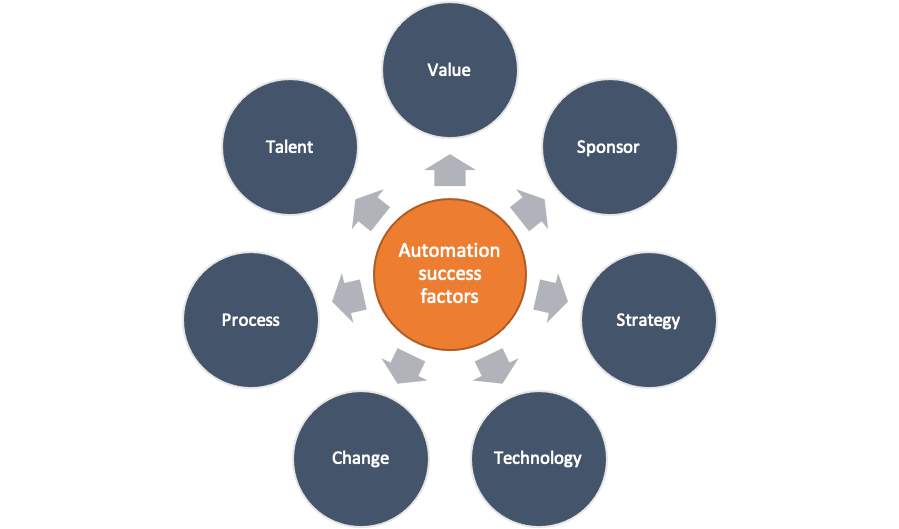

Integration and Maintenance Advantages

Pre-calibrated components reduce setup time. Compatible with Bently Nevada’s 3500/42M monitoring systems. Waterproof connectors resist corrosion. Modular parts enable swift replacements without recalibration. Diagnostic LEDs simplify troubleshooting. Minimal drift ensures long-term stability.

Why Choose PROXPAC XL for Your Operations?

It delivers unmatched accuracy in critical machinery health assessment. Reduces maintenance costs via predictive analytics. Enhances operational safety with real-time alerts. Scalable for small and large industrial setups. Trusted by global enterprises for decades.