Understanding the Need for Modernization

Modern manufacturing is under constant pressure to adapt and stay competitive. Companies must leverage smart technologies to enhance efficiency, flexibility, and reduce operational costs. The drive for agile production methods is spurred by global competition, as customers demand higher quality and faster delivery. Furthermore, the burden of regulatory compliance adds additional challenges. Embracing modernization becomes essential for manufacturers seeking sustained growth and innovation in a rapidly evolving market.

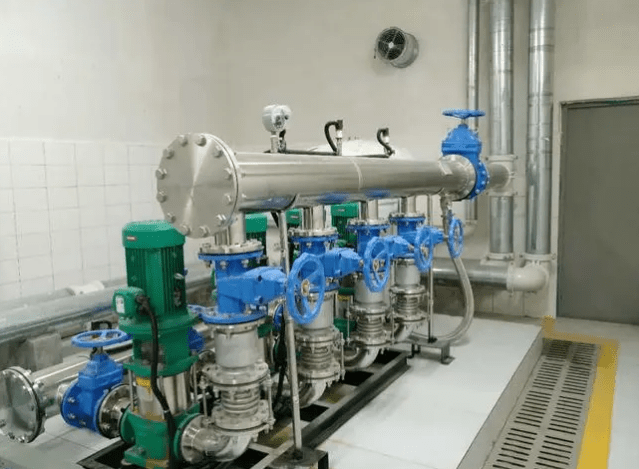

Key Smart Technologies for Existing Operations

Several pivotal technologies enable the modernization of manufacturing processes. The Internet of Things (IoT) facilitates real-time data collection, allowing manufacturers to monitor operations seamlessly. Coupled with cloud computing, which provides scalable data storage and supports substantial data analysis and application deployment, these technologies create a robust ecosystem. Additionally, artificial intelligence (AI) and machine learning (ML) offer advanced analytics that enhance decision-making. Edge computing allows for faster data processing by bringing computation closer to the data source, while digital twins create virtual replicas of physical systems, optimizing performance and maintenance.

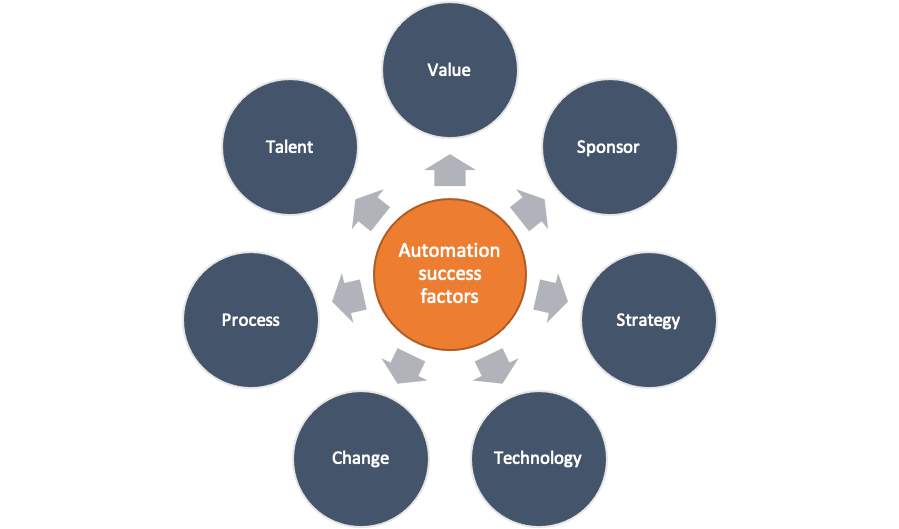

Integrating Smart Technologies: A Step-by-Step Approach

To successfully integrate smart technologies, companies should start with a clear understanding of their goals and identify specific areas for improvement. Developing a pilot program to test new technologies while ensuring compatibility with existing systems is crucial for minimizing disruption. It’s essential to define key performance indicators (KPIs) to measure success accurately. Conducting a thorough risk assessment and drafting a detailed implementation plan will pave the way for seamless integration. However, integration can be complex, particularly with legacy systems that pose compatibility issues. Comprehensive employee training and strong change management practices are critical to facilitate adoption and ensure cybersecurity measures are robust throughout the process.

The Future of Smart Manufacturing

The future of manufacturing lies in the continuous evolution of smart technologies that promise to drive further automation and efficiency. Companies must remain vigilant and committed to continuous improvement to stay competitive. As digital transformation reshapes the industry landscape, the focus will increasingly shift toward autonomous systems and sustainable practices. Manufacturers that embrace innovation can effectively address emerging challenges and exploit new opportunities, making sustainability a paramount driving force in their operational strategies.

Check below popular items for more information in Powergear X Automation Limited

| Model | Title | Link |

|---|---|---|

| 21000-28-10-30-065-04-02 | Housing Assemblies GE Bently Nevada 21000-28-10-30-065-04-02 | Learn More |

| 21000-28-00-00-039-03-02 | 21000-28-00-00-039-03-02 Proximity Probe Housing Assembly | Learn More |

| 21000-28-00-00-066-03-02 | Housing Assemblies GE Bently Nevada 21000-28-00-00-066-03-02 | Learn More |

| 21000-28-00-30-018-03-02 | 21000-28-00-30-018-03-02 GE Bently Nevada Housing Assemblies | Learn More |

| 21000-28-10-15-030-04-02 | Housing Assemblies 21000-28-10-15-030-04-02 Bently Nevada | Learn More |

| 21000-28-05-30-039-04-02 | 21000-28-05-30-039-04-02 Housing Assemblies Bently Nevada | Learn More |

| 21000-28-05-20-066-04-02 | GE Bently Nevada 21000-28-05-20-066-04-02 Housing Assemblies | Learn More |

| 21000-28-10-15-065-03-02 | 21000-28-10-15-065-03-02 GE Bently Nevada Housing Assemblies | Learn More |

| 21000-28-00-30-030-03-02 | Housing Assemblies 21000-28-00-30-030-03-02 GE Bently Nevada | Learn More |

| 21000-28-10-15-039-03-02 | GE Bently Nevada 21000-28-10-15-039-03-02 Housing Assemblies | Learn More |